Conveyors and Components

SOLUTIONS ENGINEERED FOR EFFICIENCY

Industry-Leading Conveyor Systems & Components

Jealco has been a trusted provider of high-quality conveyor systems and conveyor components for more than 75 years. Our experienced team is ready to support your project with expert guidance on installation, system integration, and equipment replacement. We offer comprehensive solutions for:

- Conveyor Rollers (metal and PVC)

- Flexible Gravity Conveyors

- Flexible Powered Conveyors

- Horizontal Belt Conveyors

- Inclined Belt Conveyors

- Roller Conveyors

- Troughed Belt Conveyors

Whether you're upgrading an existing system or building a new one, Jealco delivers reliable, efficient, and scalable conveyor solutions tailored to your operational needs.

Metal Conveyor Rollers

Conveyor rollers are the backbone of gravity and powered roller conveyor systems, providing smooth, low-friction transport for cartons, totes, pallets, and packages.

Metal rollers deliver high load capacity and durability for harsh environments.

How and Where They Work Best

Metal rollers excel in heavy-duty applications and long runs where high throughput and impact resistance are critical—think inbound receiving lines, assembly operations, and pallet handling zones.

Industries That Use This Type

- Distribution & E‑commerce

- Manufacturing & Automotive

- Food, Beverage, & Pharma

- Parcel & 3PL

PVC Conveyor Rollers

Conveyor rollers are the backbone of gravity and powered roller conveyor systems, providing smooth, low-friction transport for cartons, totes, pallets, and packages.

PVC rollers offer lightweight, corrosion-resistant performance in clean or washdown areas.

How and Where They Work Best

PVC rollers are ideal where reduced noise, lighter loads, and hygiene are key, such as packaging cells and inspection lines.

Industries That Use This Type

- Distribution & E‑commerce

- Manufacturing & Automotive

- Food, Beverage, & Pharma

- Parcel & 3PL

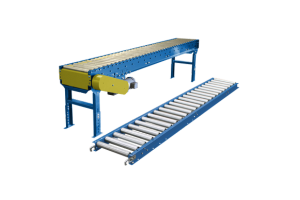

Roller Conveyors (Gravity & Powered)

Roller conveyors use rows of rollers to move boxes, totes, and pallets with low friction—either by gravity or powered rollers for controlled flow. Rugged, modular, and easy to integrate.

How and Where They Work Best

Gravity roller conveyors are cost-effective for simple movement and accumulation. Powered roller conveyors add precise zone control and automated merges.

Industries That Use This Type

- Distribution & 3PL

- Manufacturing & Automotive

- Parcel & CEP

- Retail & CPG

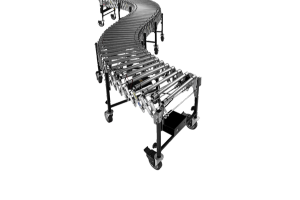

Flexible Gravity Conveyors

Flexible gravity conveyors expand, contract, and curve to fit your floor plan—no power required. Their skatewheel or roller design makes them perfect for fast setup at docks, packing stations, and pop-up fulfillment areas.

How and Where They Work Best

Ideal for truck loading/unloading, seasonal peaks, and dynamic pick/pack lines. Deploy them where you need instant flow with minimal footprint—receiving, cross-docking, returns processing, or temporary rework cells.

Industries That Use This Type

- Retail & E‑commerce Fulfillment

- Parcel & CEP

- 3PL & Warehousing

- Light Manufacturing

Flexible Powered Conveyors

Flexible powered conveyors add motorized belt or roller drive to a portable, expandable frame—delivering controlled flow, consistent speed, and improved ergonomics for high-volume docks and variable layouts.

How and Where They Work Best

Perfect for truck loading / unloading, especially for long trailers and mixed cartons where powered assist reduces strain and increases cartons-per-hour.

Industries That Use This Type

- Parcel & Last-Mile

- E‑commerce & Retail DCs

- 3PL

- Manufacturing

Horizontal Belt Conveyors

Horizontal belt conveyors provide a continuous, stable conveying surface for cartons, totes, polybags, and irregular items. Gentle handling and precise speed control make them ideal for transport between workstations.

How and Where They Work Best

Best for straight, level runs where consistent product orientation matters—feeding labelers, scanners, weigh stations, and accumulation zones.

Industries That Use This Type

- Food & Beverage

- Electronics & Consumer Goods

- E‑commerce & Retail

- General Manufacturing

Inclined Belt Conveyors

Inclined belt conveyors move products safely between elevations—mezzanines, multi-level pick modules, or between floor and dock height—while maintaining orientation and control.

How and Where They Work Best

Use them for elevation changes where chutes are too steep or rough, or where controlled spacing is required.

Industries That Use This Type

- Warehousing & E‑commerce

- Manufacturing

- Food & Beverage

- Agriculture & Consumer Goods

Troughed Belt Conveyors

Troughed belt conveyors cradle bulk materials within a formed “trough,” keeping product centered and minimizing spillage over long distances. Built for capacity and reliability.

How and Where They Work Best

Ideal for continuous transport of bulk materials—aggregates, grain, ore, biomass—across plants, yards, and quarries.

Industries That Use This Type

- Mining & Quarry

- Agriculture

- Cement & Building Materials

- Power & Biomass