Elevator Buckets

DURABLE BUCKETS FOR DEMANDING AGRICULTURAL AND INDUSTRIAL APPLICATIONS

Jealco delivers high-performance bucket elevator components designed for agriculture, grain, feed, fertilizer, and industrial applications. Our product range includes durable buckets and fasteners from trusted brands like Tapco and Maxi-Lift, ensuring maximum efficiency and reliability for your material handling systems.

Polyethylene

Jealco supplies polyethylene elevator buckets engineered for agricultural grain handling and feed processing. These buckets offer lightweight durability, excellent impact resistance, and superior corrosion protection compared to metal alternatives. Ideal for high-capacity bucket elevators, our polyethylene buckets reduce wear on belts and minimize downtime, making them a cost-effective solution for bulk material handling.

Product Facts:

- Material: Injection molded high density linear prime virgin polyethylene.

- Color: Blue (also available in white).

- Temperature Range: -60°F to + 200°F/-51°C to + 93°C.

- Flammability: The high density polyethylene used in Tapco buckets is termed “slow burning”. It has been tested under ASTM Test No. D635. It also meets the criteria for approval under the Motor Vehicle Safety Standard No. 302 and Underwriters’ Laboratory Bulletin No. 94. Combustion in an excess of air results in harmless by-products (fumes) which are nontoxic.

- Standard Drilling: No Charge.

- Special Drilling: Any pattern and hole diameter can be provided at minimal cost.

- Venting: Available in five standard patterns. See catalog for specifications. Venting page.

- Usable Capacity: Net or usable capacity could range from 10% to 20% above water level. For engineering purposes we recommend using WL (Water Level) + 10% for usable capacity.

- Spacing: Minimum bucket spacing has historically been nominal projection plus 2". Many style CC buckets, however, are being used at projection plus 1", and some even closer. For engineering purposes we recommend using nominal projection plus 2".

- Interchangeability: Can be intermixed with existing steel or nonmetallic buckets. Some consideration should be given to balance. Bucket projection varies by manufacturer and material. Check elevator for proper clearances. Contact us for recommendations.

- Installation: Fanged elevator bolts and nylon insert lock nuts are recommended for pulleys 6" in diameter and over. No. 3, Eclipse slotted head elevator bolts are recommended for pulleys under 6" in diameter. Large flat steel (fender) washers must be placed inside the bucket under the nuts. Check elevator for proper clearances.

- FDA Status: The polyethylene used meets the requirements of the Food Additives Law and Regulation No. 177.1520. Blue pigment meets Regulations No. 175.300 and 177.2600.

- UV Resistance: No UV (ultraviolet) stabilizers are added to Tapco buckets because most elevator buckets are enclosed in casings. Tapco buckets should not be exposed to direct sunlight for extended periods of time.

- Recommendations: Polyethylene buckets are ideal for use with grains, feeds, fertilizers, seeds, food products, chemicals, sand, salt and most free flowing agricultural products handled in bucket elevators.

- Limitations: Polyethylene buckets should not be used with the following: (1) Materials over 200°F/93°C. (2) Sharp edged materials such as crushed glass or oyster shells. (3) Large dense materials such as gravel and ores over 3/8" diameter. (4) A few extremely abrasive and sluggish materials such as dried whey, some pellets and extruded feeds. (5) Some severe soybean and rice applications.

- Caution: Welding and cutting on elevator legs without taking proper precautions is extremely dangerous and can cause a violent explosion. Urethane buckets can be ignited and will burn from improper welding and cutting.

- Important: When elevating materials that harden or set up with moisture, a Tapco steel digger bucket should replace every 10th urethane bucket. Contact Tapco for recommendations.

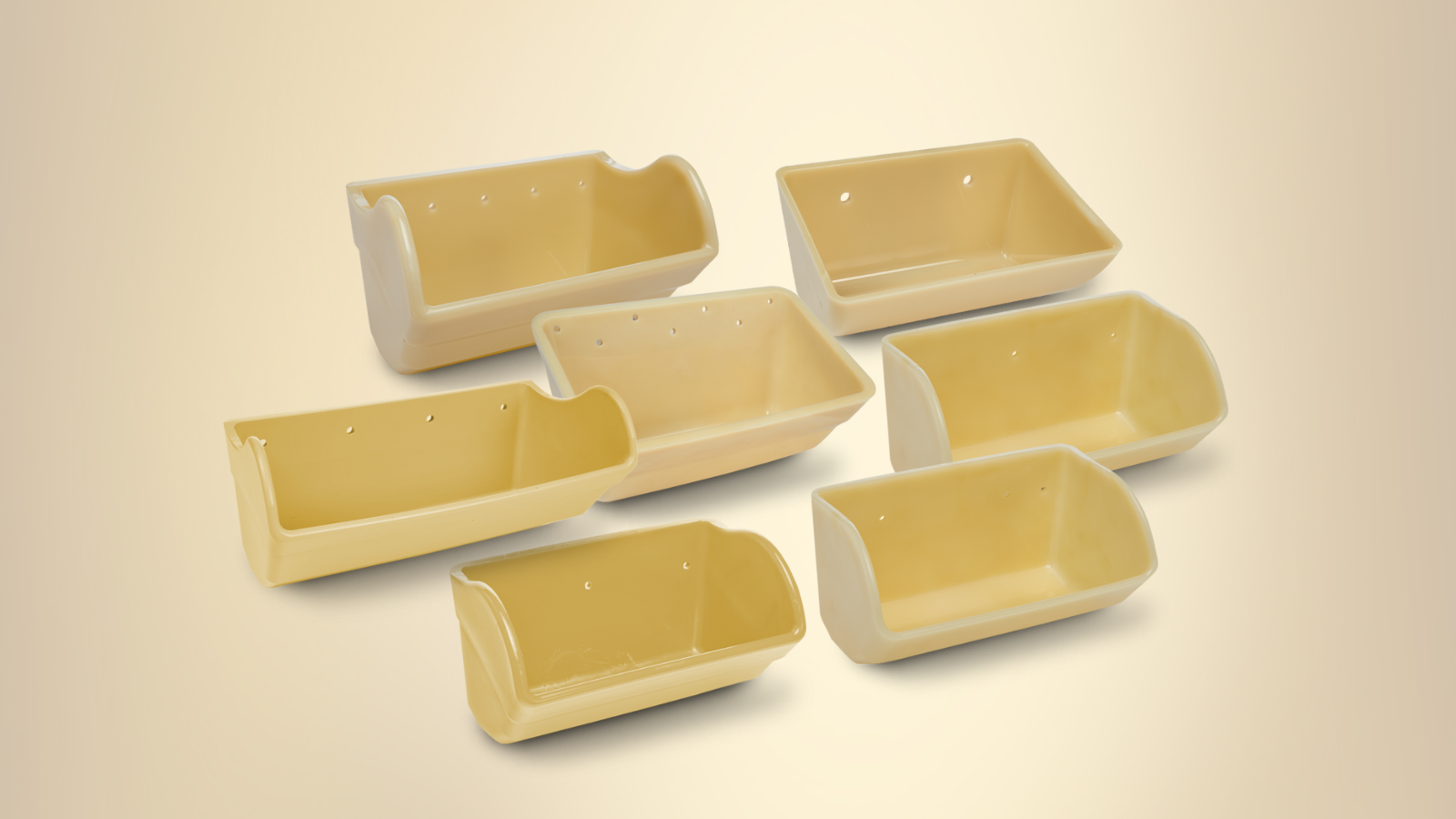

Urethane

Our urethane elevator buckets deliver exceptional abrasion resistance and long service life in demanding environments. Perfect for fertilizer, sand, and aggregate applications, these buckets withstand high-impact loading and extreme temperatures. Jealco’s urethane buckets are designed for heavy-duty bucket elevators, ensuring maximum performance and efficiency in industrial operations.

Product Facts:

- Material: Injection molded prime virgin thermoplastic urethane.

- Color: Beige (Tan).

- Temperature Range: -60°F to + 212°F/-51° C to + 100°C.

- Durometer Range: Shore D 60-70.

- Flammability: Meets the criteria of the Underwriters’ Laboratory Bulletin No. 94 HB. It has been tested under ASTM Test No. D635 and has a burn rate of 0.76”/min. it also meets approval under motor vehicle safety standard No. 302, with a burn rate of 0.0”/min.

- Standard Drilling: No Charge.

- Special Drilling: Any pattern and hole diameter can be provided at minimal cost.

- Venting: Available in five standard patterns. See catalog for specifications. Venting page.

- Usable Capacity: Net or usable capacity could range from 10% to 20% above water level. For engineering purposes we recommend using WL (Water Level) + 10% for usable capacity.

- Spacing: Minimum bucket spacing has historically been nominal projection plus 2". Many style CC buckets, however, are being used at projection plus 1", and some even closer. For engineering purposes we recommend using nominal projection plus 2".

- Interchangeability: Can be intermixed with existing steel or nonmetallic buckets. Some consideration should be given to balance. Bucket projection varies by manufacturer and material. Check elevator for proper clearances. Contact us for recommendations.

- Installation: Fanged elevator bolts and nylon insert lock nuts are recommended for pulleys 6" in diameter and over. No. 3, Eclipse slotted head elevator bolts are recommended for pulleys under 6" in diameter. Large flat steel (fender) washers must be placed inside the bucket under the nuts. Check elevator for proper clearances.

- FDA Status: Our standard urethane does not meet the requirements for FDA approval. FDA approved urethane is available as a special order.

- UV Resistance: No UV (ultraviolet) stabilizers are added to Tapco buckets because most elevator buckets are enclosed in casings. Tapco buckets should not be exposed to direct sunlight for extended periods of time.

- Recommendations: Urethane buckets are ideal for use with pelletized high fat and molasses feeds, extruded feeds, severe soybean, rice and barley applications and other abrasive agricultural products. They are excellent for extremely high throughput elevators.

- Limitations: Urethane buckets should not be used on the following: (1) Materials over 212°F/100°C. (2) Large dense materials such as gravel and ores over 3/8" in diameter. (3) Some sharp sluggish materials such as large glass cullet.

- Caution: Welding and cutting on elevator legs without taking proper precautions is extremely dangerous and can cause a violent explosion. Urethane buckets can be ignited and will burn from improper welding and cutting.

- Important: When elevating materials that harden or set up with moisture, a Tapco steel digger bucket should replace every 10th urethane bucket. Contact Tapco for recommendations.

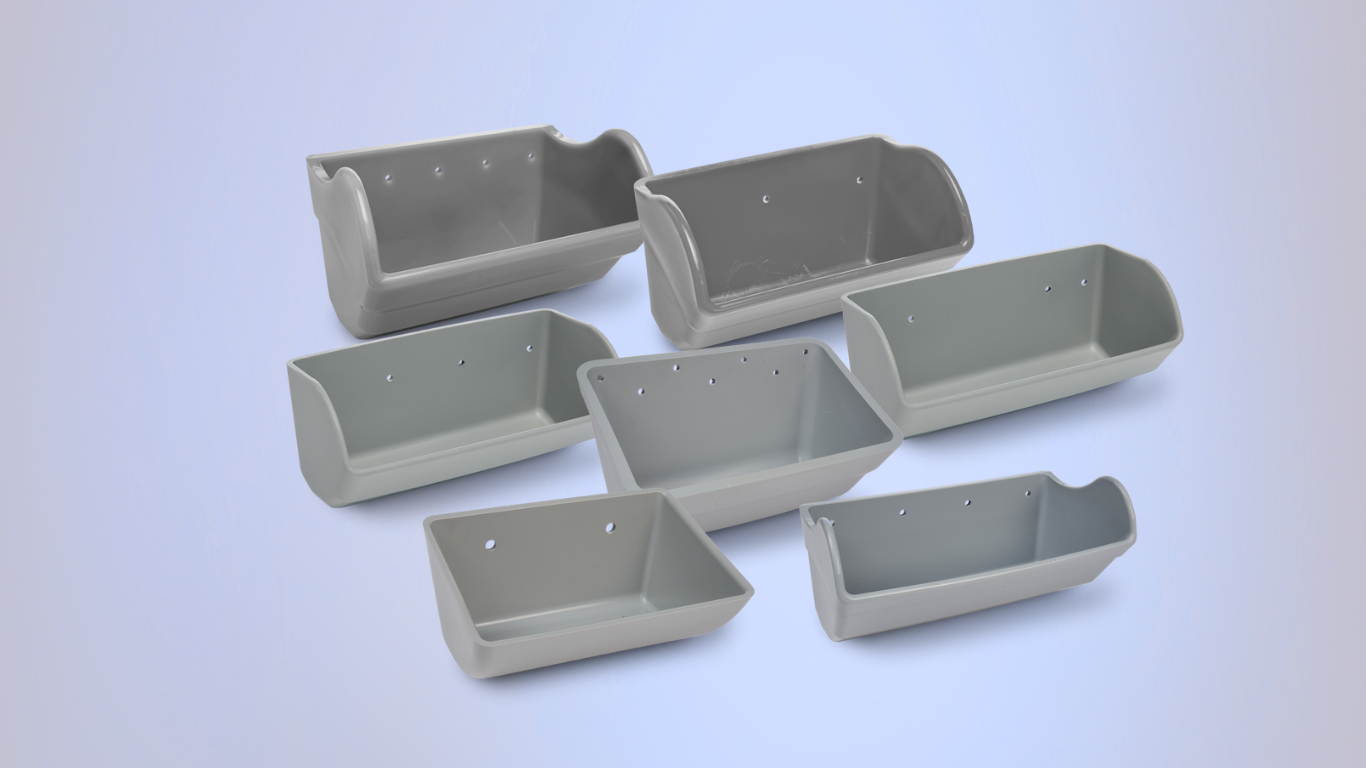

Nylon

Jealco offers nylon elevator buckets for applications requiring high tensile strength and heat resistance. These buckets excel in grain milling, feed plants, and industrial material handling, providing superior durability and dimensional stability under heavy loads. Choose nylon buckets for high-speed elevators where strength and reliability are critical.

Product Facts:

- Material: Injection molded prime virgin impact modified nylon.

- Color: Gray.

- Temperature Range: -40°F to + 275°F/-40°C to + 135°C.

- Flammability: The impact modified nylon used in Tapco buckets is termed “slow burning”. It has been tested under Underwriters’ Laboratory Bulletin No. 94 HB. The primary toxic product of combustion is carbon monoxide.

- Standard Drilling: No Charge.

- Special Drilling: Any pattern and hole diameter can be provided at minimal cost.

- Venting: Available in five standard patterns. See catalog for specifications. Venting page.

- Usable Capacity: Net or usable capacity could range from 10% to 20% above water level. For engineering purposes we recommend using WL (Water Level) + 10% for usable capacity.

- Spacing: Minimum bucket spacing has historically been nominal projection plus 2". Many style CC buckets, however, are being used at projection plus 1", and some even closer. For engineering purposes we recommend using nominal projection plus 2".

- Interchangeability: Can be intermixed with existing steel or nonmetallic buckets. Some consideration should be given to balance. Bucket projection varies by manufacturer and material. Check elevator for proper clearances. Contact us for recommendations.

- Installation: Fanged elevator bolts and nylon insert lock nuts are recommended for pulleys 6" in diameter and over. No. 3, Eclipse slotted head elevator bolts are recommended for pulleys under 6" in diameter. Large flat steel (fender) washers must be placed inside the bucket under the nuts. Check elevator for proper clearances.

- FDA Status: Impact modified nylon does not meet requirements for FDA approval.

- UV Resistance: No UV (ultraviolet) stabilizers are added to Tapco buckets because most elevator buckets are enclosed in casings. Tapco buckets should not be exposed to direct sunlight for extended periods of time.

- Recommendations: Nylon buckets are extremely strong. They are unsurpassed in rough or severe service elevators. The outstanding abrasion resistant characteristics make this an excellent bucket for grain, soybeans, feeds, fertilizer, chemicals, sand and other free-flowing products.

- Limitations: Nylon buckets should not be used in the following: (1) Materials over 275°F/135°C. (2) Large dense material such as gravel and ore over 3/8" diameter. (3) Some sharp sluggish materials such as large glass cullet or oyster shells.

- Caution: Welding and cutting on elevator legs without taking proper precautions is extremely dangerous and can cause a violent explosion. Urethane buckets can be ignited and will burn from improper welding and cutting.

- Important: When elevating materials that harden or set up with moisture, a Tapco steel digger bucket should replace every 10th urethane bucket. Contact Tapco for recommendations.

Steel & Ductile Iron

Jealco offers steel elevator buckets and ductile iron elevator buckets engineered for the most demanding bulk material handling environments. Built for industrial-grade performance, these buckets deliver exceptional impact strength, abrasion resistance, and structural integrity in abrasive, high-temperature, and heavy-duty applications. Commonly used in cement plants, aggregate facilities, mineral processing, mining, and quarrying, our buckets are available in multiple profiles for efficient material discharge, maximum capacity, and long-term reliability. Trust Jealco for durable elevator bucket solutions that withstand the toughest operating conditions.

Product Facts:

Material: Fabricated (Spot welded).Carbon Steel or Stainless Steel. The bucket utilizes a 1-piece pressed formed design consisting of two end plates and a body. Please note that there is no taper on the sides of the bucket. The bottom is spot welded to the ends.

Material Thickness: 18 ga., 16 ga., 14ga.

Flammability: The high density polyethylene used in Tapco buckets is termed “slow burning”. It has been tested under ASTM Test No. D635. It also meets the criteria for approval under the Motor Vehicle Safety Standard No. 302 and Underwriters’ Laboratory Bulletin No. 94. Combustion in an excess of air results in harmless by-products (fumes) which are nontoxic.

Standard Drilling: No Charge.

Special Drilling: Any pattern and hole diameter can be provided at minimal cost.

Venting: Contact us for more information.

Usable Capacity: We recommend using 75% of total capacity.

Spacing: Minimum bucket spacing has historically been nominal projection plus 2". Many style CC buckets, however, are being used at projection plus 1", and some even closer. For engineering purposes we recommend using nominal projection plus 2".

Interchangeability: Can be intermixed with existing steel or nonmetallic buckets. Some consideration should be given to balance. Bucket projection varies by manufacturer and material. Check elevator for proper clearances. Contact us for recommendations.

Installation: Fanged elevator bolts and nylon insert lock nuts are recommended for pulleys 6" in diameter and over. No. 3, Eclipse slotted head elevator bolts are recommended for pulleys under 6" in diameter. Large flat steel (fender) washers must be placed inside the bucket under the nuts. Check elevator for proper clearances.

Caution: Welding and cutting on elevator legs without taking proper precautions is extremely dangerous and can cause a violent explosion. Urethane buckets can be ignited and will burn from improper welding and cutting.

Fasteners

Jealco offers a wide range of elevator bolts, nuts, washers, and spacers designed for high-performance in agricultural and industrial material handling systems. Our product catalog includes fanged elevator bolts, nylon insert lock nuts, neoprene and polyethylene washers, and custom spacers, all engineered for durability and compatibility with plastic and steel elevator buckets. Jealco is a leading supplier of bulk material handling hardware, providing reliable fastening solutions for grain elevators, conveyors, and bucket elevators.